PACCAR® DEF Tank

Diesel Exhaust Fluid (DEF) is a liquid used to reduce the amount of air pollution created by a diesel engine.

Flambeau customer, PACCAR, needed a new back-of-cab DEF tank assembly for two of the company’s Kenworth® diesel heavy-duty trucks. With a successful air duct manufacturing project for PACCAR winding down, the company was convinced to turn to Flambeau again for another complex part. A smooth transition between the two projects strengthened an already fine-tuned collaborative synergy between Flambeau and PACCAR.

Precision tests and measurements would confirm peak part performance.

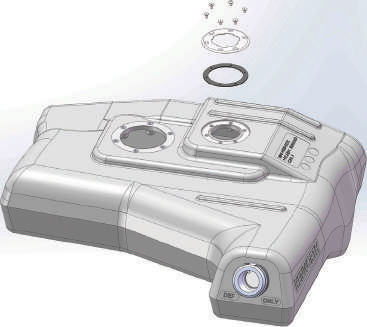

One challenge in engineering PACCAR’S tank was removing it from an existing rotational molding process and converting the part to a blow molded one. Flambeau engineers calculated the correct blow ratios and an extremely precise wall thickness to ensure none of the limitations of blow molding would affect PACCAR’s tank. Precision tests and measurements would confirm peak part performance.

Flambeau found a solution.

Flambeau engineers also redesigned the tank as a three-piece component, because the part’s required bayonet lock ring could not be molded in place. This is an example of a part not being “blow moldable.” Their solution was to sandwich a gasket between the bayonet ring and the over-molded tank ring. Flambeau found a solution

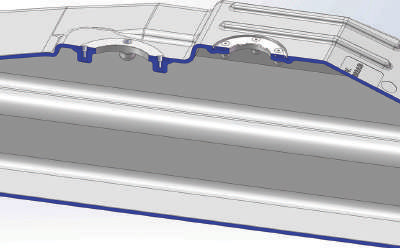

Designing the new tank to be mounted above the trucks’ fuel tanks and under the cab, provided space for larger fuel tanks, giving the trucks more mileage per fill up.

Blow molding process optimized to allow for the best running condition.

Another key design detail was to orientate the over-molded inserts in a way that optimized the blow molding process and allow the best running condition. The over-molded neck and the component inserts were additional features that would make this part unique. In the post-mold phase of manufacturing the part, the final assembly would include installation of screws to a precise torque requirement.

Designed for increased fuel capacity it also included improved installation.

PACCAR’s new tank was designed to maximize fuel capacity, as well as enable improved installation capabilities in its two trucks. The new tank configuration ended up approximately 25 pounds under the weight of a standard-mounted DEF tank. Also, by designing it to be mounted above the trucks’ fuel tanks and under the cab, space was now available for larger fuel tanks, giving the trucks more mileage per fill up.

Flambeau as a partner.

Flambeau brings its best design, engineering, and production capabilities to a project, and its priority is always to meet customer requirements of quality, fulfillment and cost. With Flambeau as its partner, customers like PACCAR can count on getting the maximum mileage out of the vital parts defining their projects.

trucks’ fuel tanks and under the cab

(as shown to the left), space was now

available for larger fuel tanks, giving

the trucks more mileage per fill up.