Blow Molding

- Home

- Capabilities

- Blow Molding

Advanced Blow Molding Solutions

Blow Molding

In 1961, Flambeau added blow molding to their capabilities. Flambeau now has over 100 blow molding machines ranging in size from 1 to 40 pound shot in its facilities around the world. Each Flambeau facility adheres to the quality and environmental standards in manufacturing, as set by the International Organization for Standardization (ISO), with multiple certifications including ISO 13485, ISO 14001, and ISO 9001, as well as IATF 16949. With on-site quality control laboratories at each facility, Flambeau ensures the highest levels of quality in plastics manufacturing. See our facilities page to learn which certifications apply to what facility locations.

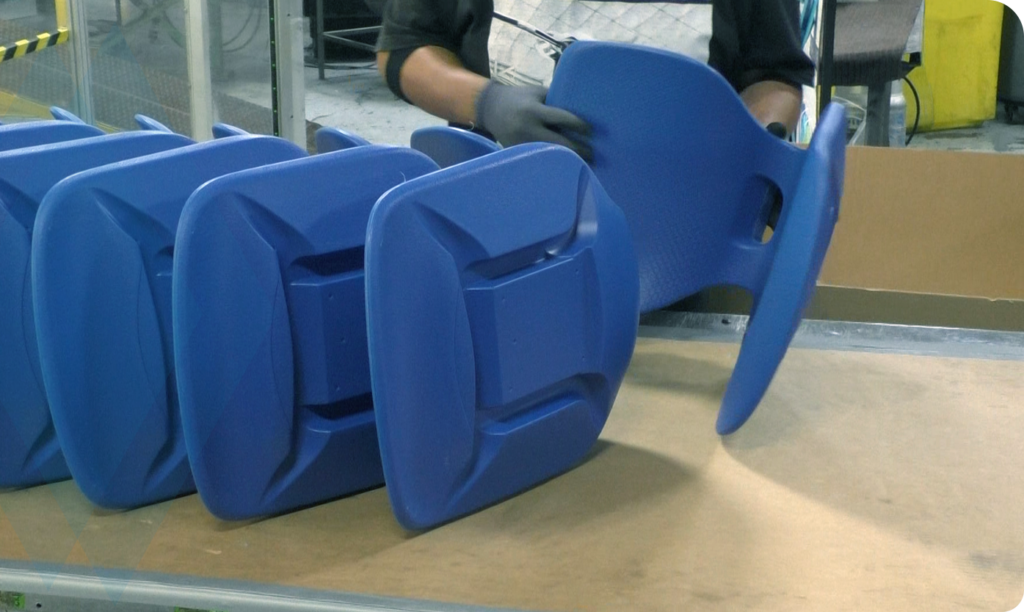

Flambeau serves customers within a diverse range of markets including appliance, automotive, electronic, heavy truck, industrial equipment, lawn and garden, medical, recreation, telecommunication, premiums and packaging sectors by providing quality blow molded thermoplastic parts.

We can provide design assistance or complete product design through our in-house Technology Center where we have technical resource who specialize in blow molding. We can design and build prototype and production tools, as well as, provide complete program management and automated secondary operations.

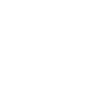

Whether your need is in extrusion blow molding, suction blow molding or continuous blow molding in a wide variety of resins, Flambeau is able to offer the process that is best suited for your application.

Key Benefits of Blow Molding

- Versatility: Capable of producing a variety of shapes and sizes, blow molding is ideal for creating complex hollow parts.

- Efficiency: The blow molding process is highly efficient, allowing for rapid production of large quantities of uniform products.

- Cost-Effective: Blow molding is a cost-effective manufacturing method due to its relatively low tooling costs and high production rates.

- Durability: Products created through blow molding are known for their strength and durability, making them suitable for demanding applications.

- Customization: Our blow molding services offer a high degree of customization, enabling us to meet specific client requirements and industry standards.

Products Manufactured Using Blow Molding

Bottles

Containers

Automotive Parts

Industrial Parts

Household Items

Medical Supplies

Tool Cases

Playground Equipment

Markets Served

Our Videos

Tech Reports

Benefits of Diversification – Medical Flambeau Medical Markets Group is in a unique position to fulfill your medical component requirements. Flambeau represents three quarters of a century of built-up accumulated expertise in thermoplastic molding. Customers experience for themselves the breadth and depth of knowledge acquired by the people of Flambeau when deployed on their project. […]

PACCAR® DEF Tank Diesel Exhaust Fluid (DEF) is a liquid used to reduce the amount of air pollution created by a diesel engine. Flambeau customer, PACCAR, needed a new back-of-cab DEF tank assembly for two of the company’s Kenworth® diesel heavy-duty trucks. With a successful air duct manufacturing project for PACCAR winding down, the company […]

3D Scanning Flambeau utilizes the latest technologies in order to provide its customers with high quality, precisely engineered products. Engineers with Flambeau Technology Center (FTC) in Baraboo, Wisconsin, utilize a state-of-the-art 3D scanner by Hexagon® Manufacturing Intelligence that assists Flambeau in maintaining its high standards of excellence for its products and services. The RS6 scanner […]

Our Work in Action

Our Engineering and Manufacturing Projects

Automotive Fuel Tanks

HVAC Air Ducts

Septic Tanks

tanks designed to meet specific environmental regulations and customer requirements…