Capabilities

- Home

- Capabilities

Flambeau Manufacturing Capabilities

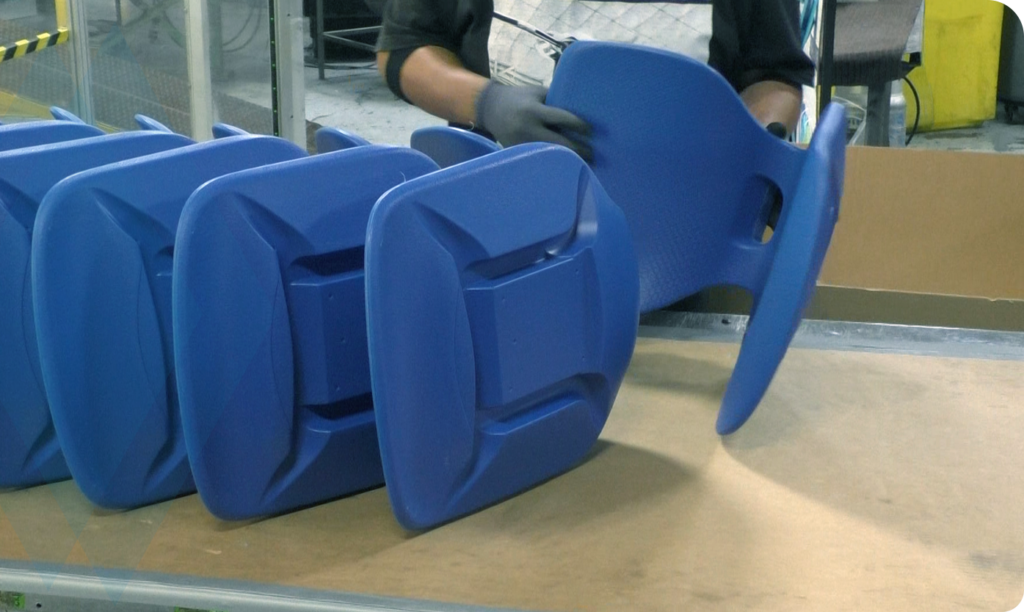

Flambeau has over 75 years of experience in the plastics industry of working with their customers to deliver contract mold custom products to exacting quality, cost and delivery specifications across a wide range of markets.

With multiple plant locations throughout the United States, Europe and Mexico, Flambeau offers truly global contract manufacturing capabilities. Each Flambeau facility adheres to the quality and environmental standards in manufacturing, as set by the International Organization for Standardization (ISO), with multiple certifications including ISO 13485, ISO 14001, and ISO 9001, as well as IATF 16949. With on-site quality control laboratories at each facility, Flambeau ensures the highest levels of quality in plastics manufacturing. See our facilities page to learn which certifications apply to what facility locations.

Before you select your next plastics manufacturing partner, contact us. We have the people, processes and resources to meet your contract manufacturing needs.

- Nine domestic manufacturing facilities to minimize distribution costs

- Global manufacturing presence (Mexico and UK)

- Sales and Engineering Offices in; Phoenix, Arizona; Auburn Hills, Michigan; Middlefield, Ohio; Baraboo, Wisconsin; Ramsgate, England; and Shenzhen Guangdong, China.

- Experienced staff providing innovative and optimized solutions to our customers’ requirements

- Global sourcing team for components and complementary products we do not manufacture

- Ability to design and manufacture a broad range of plastic products

- In-house tool making capabilities and facilities

- Specify and deliver fully automated solutions from concept to implementation

Manufacturing versatility with expertise in multiple processes:

- Injection Molding: 24 Ton — 1,700 Ton

- Blow Molding: Up to 40 Pound Shot – Accumulator and Continuous Extrusion

- Gas Assist Molding

- Over-Molding

- Insert Molding

- Clean Room Molding – Class 7 and Class 8

- Global sourcing team for components and complementary products we do not manufacture

Our Core Capabilities

Blow Molding

Injection Molding

Secondary Operations

Tooling

Product Design

Project Management

Prototyping

Automation

Tech Reports

Diversification – Medical

Benefits of Diversification – Medical Flambeau Medical Markets Group is in a unique position to fulfill your medical component requirements. Flambeau represents three quarters of a century of built-up accumulated expertise in thermoplastic molding. Customers experience for themselves the breadth and depth of knowledge acquired by the people of Flambeau when deployed on their project. […]

Custom Medical Device Enclosures

Durable Consumer Goods Packaging

Benefits of Diversification – Medical Flambeau Medical Markets Group is in a unique position to fulfill your medical component requirements. Flambeau represents three quarters of a century of built-up accumulated expertise in thermoplastic molding. Customers experience for themselves the breadth and depth of knowledge acquired by the people of Flambeau when deployed on their project. […]

PACCAR® DEF Tank Diesel Exhaust Fluid (DEF) is a liquid used to reduce the amount of air pollution created by a diesel engine. Flambeau customer, PACCAR, needed a new back-of-cab DEF tank assembly for two of the company’s Kenworth® diesel heavy-duty trucks. With a successful air duct manufacturing project for PACCAR winding down, the company […]

3D Scanning Flambeau utilizes the latest technologies in order to provide its customers with high quality, precisely engineered products. Engineers with Flambeau Technology Center (FTC) in Baraboo, Wisconsin, utilize a state-of-the-art 3D scanner by Hexagon® Manufacturing Intelligence that assists Flambeau in maintaining its high standards of excellence for its products and services. The RS6 scanner […]

Ready to Collaborate?

Discover how Flambeau’s cutting-edge manufacturing capabilities can bring your project to life. Our team of experts is ready to assist you from concept to completion. Get in touch today to learn more about our services or to start your next project.